Hemp Drying Applications

Hemp is gaining acceptance as a legal form of medication, with untapped potential in many other applications. With the increase of popularity and mainstream approval, the hemp growing and drying industry is booming. Laws have shifted to allow certain growth, processing and transportation of hemp—even across state lines. Improving on the hemp drying process will mean providing a higher quality product and decreasing product loss.

Drying Hemp to Extract CBD Oil

An essential part of processing hemp is in reducing the moisture of the plant. The processing time of hemp can be significant, but the hemp biomass has to be dried to an acceptable level in order to harvest the CBD oil. This drying process needs to occur as quickly as possible to avoid deterioration and preserve the CBD.

Hemp is often hung upside down and dried by hand. The stems are removed and then the plants are cut into small pieces to dry more thoroughly. This is a time-consuming process that leaves little room for error. If the hemp is dried too slowly, the resulting product could be ruined or low-quality.

Only when the hemp has been fully dried and processed can it be sent to a CBD processing facility. At the facility, the CBD oil will be extracted from the biomass material, leaving crude CBD-rich hemp oil. That CBD is further refined into products that can be used for medications, oils or capsules.

The Right Equipment to Speed Hemp Drying

The long and tedious process of drying hemp can be sped up for more efficient and consistent results. The right equipment will help prepare the biomass for CBD oil extraction, ensuring your product is the best quality you can get from your hemp plants. You need a hemp dryer that is gentle on CBD and consistent in getting top results.

IEC Thermo is the world’s leader in hemp drying solutions, selling industrial-scale dryers since 2009. Our hemp growing clients have been able to improve the efficiency and thoroughness of their drying process by incorporating our hemp dryers–resulting in reduced overhead costs. We have the knowledge and experience to help businesses like yours really get off the ground. With customizable layouts and 2 minute dry times, our CBD-friendly drying machines meet the unique needs of your business to produce a quality final product.

Our system will reduce hemp biomass moisture from the standard 70+% down to the preferred 10-12%, within 2 minutes, all while protecting your cannabinoids and profitability. Our dryers come in 3 sizes to fit any business- 1 ton up to 8 tons per hour, speeding up the drying process and getting the product to market faster.

Depending on where you live and how the weather changes, drying times and efficiencies are likely to change a lot. A machine built for hemp drying provides a consistency to your process that you can count on.

Thinking Towards the Future of CBD

Perhaps you are just starting out and unsure if you need an industrial-sized hemp drying system. We are here to help and look at your process. If you want to grow in the hemp and CBD oil industry, you will want to produce a top-quality product. Our custom-designed hemp drying system is ideal for improving the process of hemp drying.

Not only can our drying machine help you now, it will help you grow into a larger operation. IEC dryers can grow and scale with you. Think ahead towards future growth with a machine that makes it possible to grow and process more plants at top quality. You won’t want to risk ruined products because your business demands grow faster than your processing capabilities. A larger drying machine will be ready to take on whatever level of product you need to get processed as your business grows.

IEC Thermo hemp dryers are engineered to be the fastest and the gentlest on hemp biomass. Whether you are growing for cannabinoids, or other parts of the plant, your chosen drying technology makes all the difference in the quality of your end product.

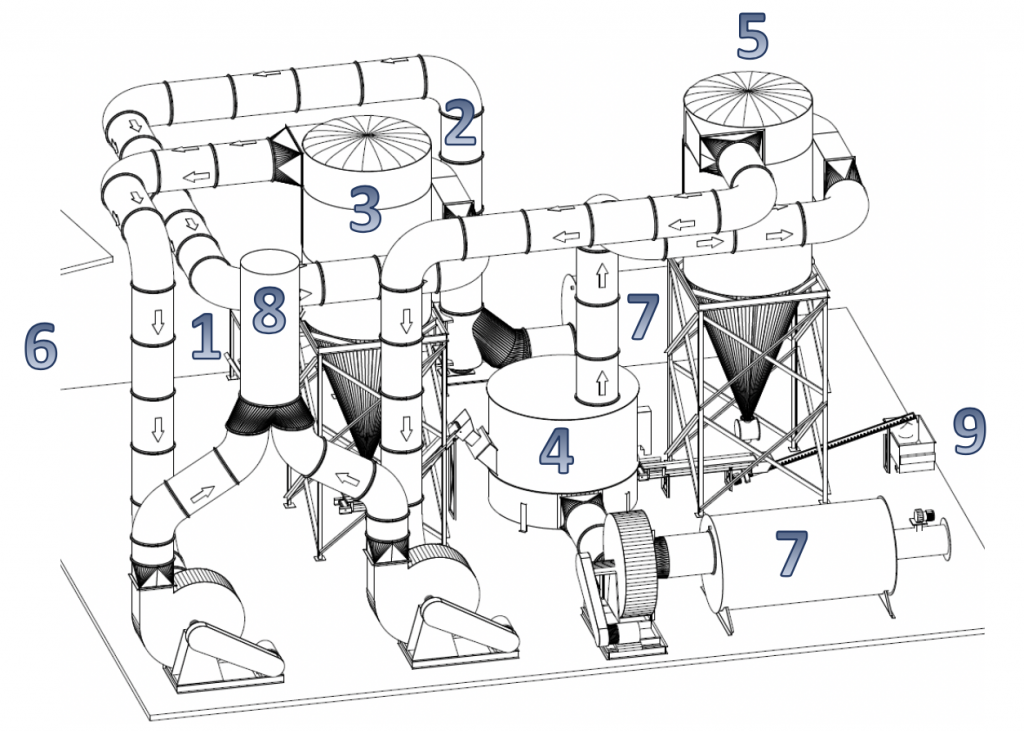

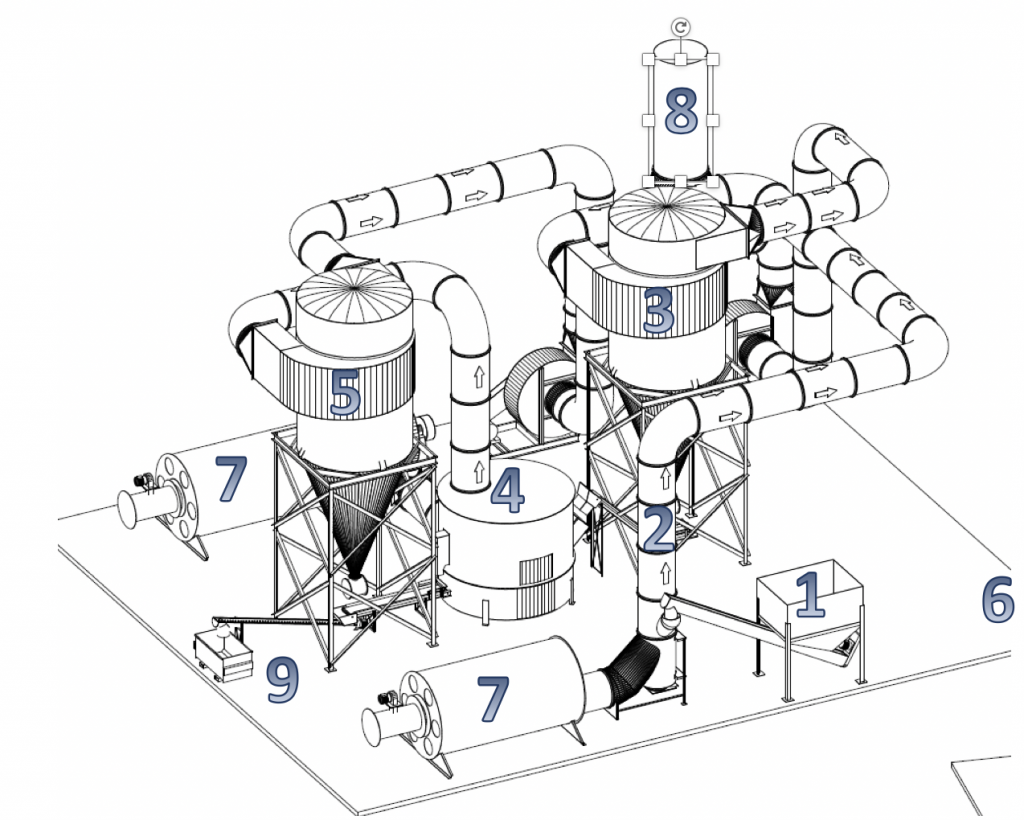

Metered Feed Hopper (#1)

Flash dryer (#2)

Flash Dryer Cyclone (#3)

Fluid bed (#4)

Fluid bed Cyclone (#5)

MCC/PLC (#6)

Burners (#7)

Exhaust (#8)

Output Conveyor (#9)

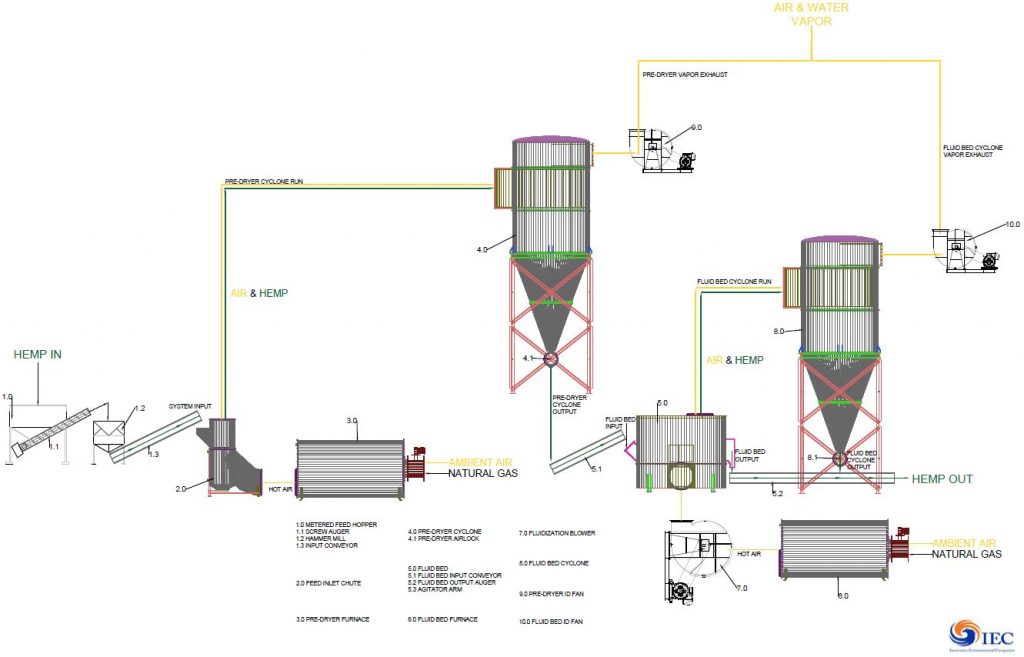

Metered Feed hopper– Chopped material enters an IEC HEMP Dryer through the metered feed hopper. Proper feeding ensures continuous flow process. Material can be conveyed, dumped, or loaded into the hopper, based on customer’s chosen input method. In under 2 minutes, product will output on the other end of the system at under 10% moisture.

— A) Hammer Mill: Recommended to produce discrete free flowing feed, allowing for larger variability.

Flash Dryer– In the first stage of the process, hemp biomass is flash dried to evaporate the majority of water very rapidly. In this phase, the product is in the system for approximately only 1-2 seconds.

Flash Dryer Cyclone– After the flash dryer, hemp product is cooled down through the separation of warm air and semi-dry hemp through the cyclone, as air is exhausted from the top of the cyclone and hemp from the bottom. No heat is applied during this process. This ensures product doesn’t reach temperatures that allow for degradation.

Fluid Bed– In the second stage of this process, semi-dry material is added to a fluid bed, with warm air being applied from below (like an air hockey table) creating lift and flow of material. Product bounces around in this stream of air until dry. This eliminates the rest of the contained water/moisture while still being gentle on the material.

Fluid Bed Cyclone– After the fluid bed dryer, hemp product is separated and cooled down a second time through another cyclone. No heat is applied during this process. This ensures product doesn’t reach temperatures that allow for degradation.

MCC/PLC– The IEC dryer system is automated by an MCC (Motor Control Center) and PLC (Programmable Logic Controller) which controls and tracks dryer operation. With one-button start and stop, programmed sequences, and operations oversight, this “computer brain” automates the dryer system.

Burners– IEC Thermo’s systems use 2 burners that are integrated into the system. These burners can be fueled by natural gas or liquid propane. No hemp product ever directly contacts the burners.

Exhaust– Moisture exhausts out a vent on the roof in the form of water vapor. There are no particulates exhausted.

Output conveyor– Dried material outputs into chosen storage method (totes, super sacks, etc.).

Interested in learning more?

Contact us today to see how a hemp drying machine could speed up your hemp drying process and improve your product!